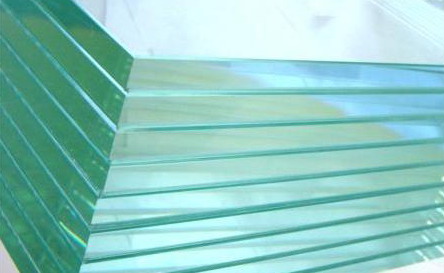

EVA film rolls for laminated glass storage guideline.

To properly store EVA film rolls for laminated glass, follow these guidelines: Use a First-In, First-Out System: Always use up older film rolls before opening a newer one to maintain the quality and performance of the laminated glass. Avoid Overlapping Rolls: Ensure that film rolls are not overlapped to prevent damage and ensure proper bonding…